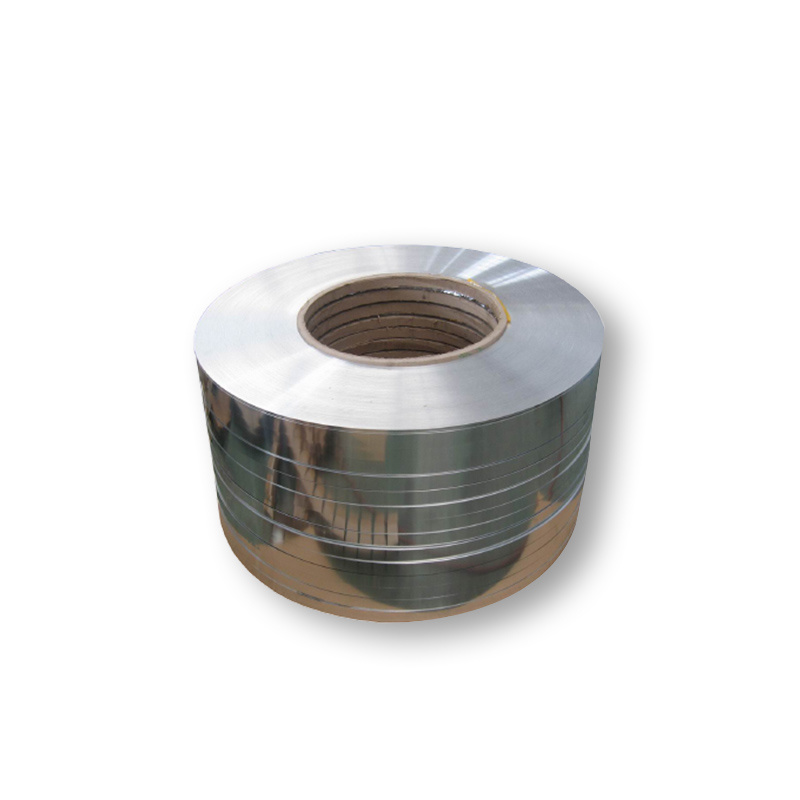

Inconel 625 Coil

- OriginChina

- Delivery Time≥7 days

- DemandCustomizable

- StandardASTM, AISI, JIS, GB, DIN, EN

- MOQ 1 Ton

- Mob: +8618191906640

- Email: info@cjmstainlesssteel.com

Inconel 625 Coil Description

The strength of Inconel 625 coil comes from the solid solution strengthening effect of molybdenum and niobium contained in the nickel-chromium alloy. These elements also give the alloy excellent corrosion-resistant properties. While the alloy is designed for strength in high-temperature environments, its highly alloyed composition gives it a high degree of resistance to general corrosion as well as resistance to a wide range of oxidizing and non-oxidizing environments. The chromium and molybdenum content make the alloy have excellent resistance to corrosion spots caused by chloride ions, and the high nickel content enhances the alloy’s resistance to chloride stress corrosion cracking. The material is highly formable and easier to weld than many nickel-based alloys. Even under welded conditions, the alloy still has the ability to resist intergranular corrosion, in addition to corrosion and oxidation resistance.

Product Parameters

| Product Name | Inconel 625 Coil |

| Thickness | 2.5mm-10.0 mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Width | 610-2000 mm |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Certificate | ISO, SGS, BV |

| Production Technology | Hot Rolling, Cold Rolling |

Chemical Composition

| C | Mg | Al | Si | P | S | Ti | Cr | Fe | Co | Ni | Mo | Cb (Nb Ta) |

| 0.1 max | 0.5 max | 0.4 max | 0.5 max | 0.015 max | 0.015 max | 0.4 max | 20.00 – 23.00 | 5.0 max | 1.0 max | 58.0 min | 8.0 – 10.0 | 3.15 – 4.15 |

Mechanical Properties

| Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

| 120 | 60 | 30 |

Physical Performance

| Units | Temperature in°C | |

| Density | 8.44 g/cm³ | Room |

| Specific Heat | 0.098 Kcal/kg.C | 21° |

| Melting Range | 1290-1350°C | – |

| Modulus of Elasticity | 207.5 KN/mm² | 21° |

| Electrical Resistivity | 129 µΩ.cm | 21° |

| Coefficient of Expansion | 12.8 µm/m °C | 21 – 93° |

| Thermal Conductivity | 9.8 w/m-° K | 21° |

Scope of Application

This alloy is resistant to a variety of severe corrosive environments, especially to pitting and crevice corrosion. Some applications of Inconel 625 are used as part of chemical processing, aerospace, and marine engineering, pollution control equipment, and nuclear reactors.pyrolysis piping systems, electric heating unit jackets and food processing equipment.d crevice corrosion. Some applications of Inconel 625 are used as part of chemical processing, aerospace, and marine engineering, pollution control equipment, and nuclear reactors.lloy 601 in a strongly reduced sulfur-containing environment.

C.J.M.Stainless Steel Group Ltd

C.J.M.Stainless Steel Group Ltd