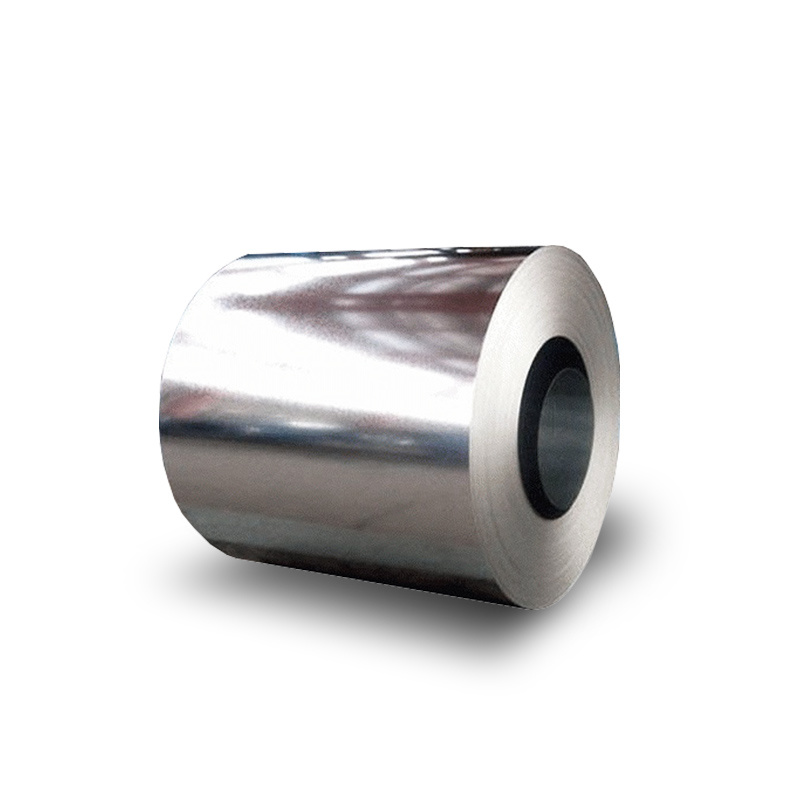

Inconel 601 Coil

- OriginChina

- Delivery Time≥7 days

- DemandCustomizable

- StandardASTM, AISI, JIS, GB, DIN, EN

- MOQ 1 Ton

- Mob: +8618191906640

- Email: info@cjmstainlesssteel.com

Inconel 601 Coil Description

Inconel 601 is a nickel-based high-temperature alloy whose main components are nickel, chromium, aluminum and iron. Among them, nickel accounts for the majority, with a content generally above 58%, while chromium and aluminum account for about 19% and 1.0% respectively. In addition, it also contains small amounts of elements such as copper and manganese, which can enhance the strength and corrosion resistance of the material. Inconel 601 coil has excellent high temperature strength, corrosion resistance and oxidation resistance. At high temperatures, its strength and hardness can be maintained at a high level, while having good plasticity and toughness. In an acidic environment, Inconel 601 coil exhibits good corrosion resistance and can effectively resist erosion by corrosive media such as chloride ions and sulfides.

Product Parameters

| Product Name | Inconel 601 Coil |

| Thickness | 2.5mm-10.0 mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Width | 610-2000 mm |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Certificate | ISO, SGS, BV |

| Production Technology | Hot Rolling, Cold Rolling |

Chemical Composition

| C | Al | Si | S | Cr | Mn | Fe | Ni | Cu |

| 0.1 max | 1.0-1.7 | 0.5 max | 0.015 max | 21.0-25.0 | 1.0 max | Remainder | 58.0-63.0 | 1.0 max |

Mechanical Properties

| Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

| 80 | 30 | 30 |

Physical Performance

| Units | Temperature in°C | |

| Density | 8.11 g/cm³ | Room |

| Specific Heat | 0.107 Kcal/kg.C | 20° |

| Melting Range | 1360-1411°C | – |

| Modulus of Elasticity | 206.5 KN/mm² | 20° |

| Electrical Resistivity | 118 µΩ.cm | 20° |

| Coefficient of Expansion | 13.75 µm/m °C | 20 – 100° |

| Thermal Conductivity | 11.2 w/m-° K | 20° |

Scope of Application

The 601 characteristics of Inconel make it widely used in the fields of heat treatment, chemical treatment, pollution control, aerospace and power generation. Therefore, it is not recommended to use the alloy 601 in a strongly reduced sulfur-containing environment.conel 625 are used as part of chemical processing, aerospace, and marine engineering, pollution control equipment, and nuclear reactors.lloy 601 in a strongly reduced sulfur-containing environment.

C.J.M.Stainless Steel Group Ltd

C.J.M.Stainless Steel Group Ltd