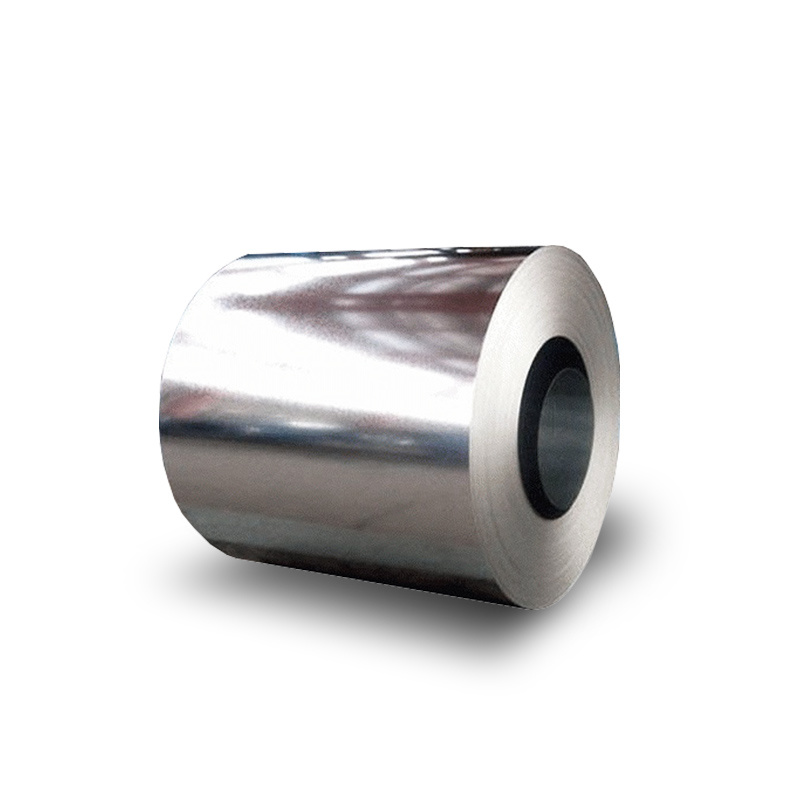

Incoloy 800H / 800HT Coil

- OriginChina

- Delivery Time≥7 days

- DemandCustomizable

- StandardASTM, AISI, JIS, GB, DIN, EN

- MOQ 1 Ton

- Mob: +8618191906640

- Email: info@cjmstainlesssteel.com

Incoloy 800H / 800HT Coil Description

Incoloy 800H is a nickel-based alloy containing approximately 22% chromium, 39% iron, and 33% nickel, with the balance being carbon, silicon, manganese and other elements. This alloy has excellent high temperature resistance, its maximum operating temperature can reach 1100°C, and it also has good toughness and ductility at room temperature. In addition, Incoloy 800H also has excellent oxidation resistance and corrosion resistance, and can maintain a long service life in high temperature environments. Incoloy 800H coil has good processing properties and can be used for hot and cold processing. During thermal processing, the heating temperature and cooling rate should be controlled to avoid cracks and deformation.

Product Parameters

| Product Name | Incoloy 800H / 800HT Coil |

| Thickness | 2.5mm-10.0 mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Width | 610-2000 mm |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Certificate | ISO, SGS, BV |

| Production Technology | Hot Rolling, Cold Rolling |

Chemical Composition

| C | Al | Si | S | Ti | Cr | Mn | Fe | Ni | Cu |

| 0.1 max | 0.15 – 0.60 | 1.0 max | 0.015 max | 0.15 – 0.60 | 19.0 – 23.0 | 1.5 max | 39.5 min | 30.0 – 35.0 | 0.75 max |

Mechanical Properties

| Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

| 75 | 30 | 30 |

Physical Performance

| Units | Temperature in°C | |

| Density | 7.94 g/cm³ | Room |

| Specific Heat | 0.11 Kcal/kg.C | 21° |

| Melting Range | 1357-1385°C | – |

| Modulus of Elasticity | 196.5 KN/mm² | 20° |

| Electrical Resistivity | 98.9 µΩ.cm | 20° |

| Coefficient of Expansion | 14.4 µm/m °C | 20 – 100° |

| Thermal Conductivity | 11.5 w/m-° K | 20° |

Scope of Application

Used in industrial furnaces, heat treatment equipment, chemical and petrochemical processing, superheaters and reheaters in power plants, pressure vessels, heat exchangers, etc.gineering, pollution control equipment, and nuclear reactors.lloy 601 in a strongly reduced sulfur-containing environment.

C.J.M.Stainless Steel Group Ltd

C.J.M.Stainless Steel Group Ltd